Description

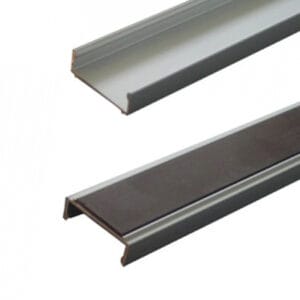

Premium Flat Bars: Advanced Solutions for Construction

Flat bars are versatile steel products with superior strength and adaptability, making them ideal for various construction and industrial applications. Their exceptional durability and workability make them perfect for structural support, fabrication, and reinforcement projects. These products are specifically designed and manufactured to meet the highest standards in the industry. They undergo rigorous quality control processes to ensure they are durable, reliable, and suitable for a wide range of applications. Whether you’re working on a small residential project or a large industrial development, these materials provide the strength and support needed to ensure the success of your construction. Their versatility and adaptability make them an essential component in modern engineering and architecture.

Read More

What Are Flat Bars?

These steel products are versatile structural components manufactured with a flat, rectangular cross-section. As defined by the World Steel Association, these bars are precision-engineered for optimal strength and workability. The manufacturing process ensures consistent dimensions and material properties, making them ideal for projects requiring reliable performance and easy fabrication. Their uniform shape enables excellent weldability and versatile application options.

Manufacturing Process

The production of Flat Bars involves several critical stages:

- Material Selection

- Premium-grade steel selection

- Raw material quality verification

- Dimensional specification check

- Steel grade certification

- Material composition analysis

- Production Process

- Precision rolling operations

- Thickness control monitoring

- Surface finish inspection

- Dimensional accuracy check

- Quality standard verification

- Quality Assurance

- Structural integrity testing

- Material property verification

- Surface finish inspection

- Load capacity certification

- Dimensional accuracy confirmation

Maintenance and Care

To ensure optimal performance:

- Regular structural inspections

- Surface treatment maintenance

- Proper storage protocols

- Load capacity monitoring

- Corrosion prevention measures

Advantages Over Traditional Methods

Flat bars offer significant benefits:

- Strength Benefits

- High tensile strength

- Superior durability

- Excellent load capacity

- Consistent material properties

- Optimal stress distribution

- Performance Benefits

- Enhanced workability

- Excellent weldability

- Superior fabrication properties

- Long-term reliability

- Weather resistance capabilities

- Application Benefits

- Versatile installation options

- Easy customization

- Efficient integration

- Cost-effective solutions

- Multiple design applications

Environmental Impact

Contributing to sustainable construction:

- Recyclable materials

- Extended service life

- Efficient material usage

- Minimal waste production

- Sustainable manufacturing process

FAQs

Q: What are the standard sizes available for Flat Bars?

A: We offer sizes ranging from 12mm to 300mm in width, with various thickness options.

Q: What is the typical delivery time?

A: Standard sizes are available within 5-7 business days. Custom orders may require additional processing time.

Q: Do you offer custom fabrication services?

A: Yes, we provide cutting, drilling, and other customization services to meet specific project requirements.

Would you like me to expand on any particular section or add more technical details?

Technical Specifications

Width – Thickness – Status

1/2″ to 12″ – 2mm to 25mm – Readily Available

Above 12″ – 2mm to 25mm – Please call for inquiries.

- Widths: Available in a variety of widths to accommodate different project requirements.

- Thicknesses: Offered in multiple thicknesses, which can be selected based on the structural needs of the project.

- Lengths: Standard length of six (6) meters is available.

- Standards: Produced according to international standards to ensure quality and consistency.

You may also send us an email at info@davaogoldenhardware.ph or send us a message here for more inquiries.

Applications and Uses

Flat bars are versatile structural components widely used across various industries due to their strength, flexibility, and ease of fabrication. Some common applications include:

- Construction & Infrastructure – Used for support structures, frames, and brackets in buildings, bridges, and industrial facilities.

- Manufacturing & Fabrication – Essential for machinery parts, welded frames, and custom metalwork.

- Automotive & Transportation – Applied in chassis manufacturing, trailers, and railways for added durability.

- Shipbuilding – Used in marine structures and ship frames due to their corrosion resistance in certain alloys.

- Home & Commercial Use – Found in gates, fences, shelving, and furniture for structural reinforcement.

- Electrical & Engineering – Utilized in grounding systems and electrical panel supports.