As a construction professional in the Philippines, selecting the right materials for foundation and retention systems can determine project success. Among the critical components in civil engineering, steel sheet piles stand out for their versatility, durability, and efficiency in challenging environments.

This comprehensive guide covers everything you need to know about steel sheet piles—from basic definitions to advanced applications—with specific considerations for Philippine construction conditions. Whether you’re developing waterfront infrastructure in Davao or managing groundwater on a major project elsewhere in the archipelago, this resource will help you make informed decisions.

What is a Steel Sheet Pile?

Steel sheet piles are interlocking structural sections made from high-strength steel. These profiles are designed to be driven into the ground to form a continuous wall or barrier. The interlocking system creates a watertight seal, making steel sheet piles ideal for applications where groundwater control is essential.

Key Structural Properties

These engineered elements provide exceptional resistance against lateral earth pressures while maintaining structural integrity over extended periods. Modern steel sheet piles offer:

- High section modulus: Providing superior bending resistance

- Optimized weight-to-strength ratio: Enabling efficient handling and installation

- Precise interlocking systems: Ensuring continuity and watertightness

- Corrosion resistance options: Various treatments available for marine environments common in the Philippines

Learn more about steel sheet pile engineering fundamentals

Comparison with Alternative Solutions

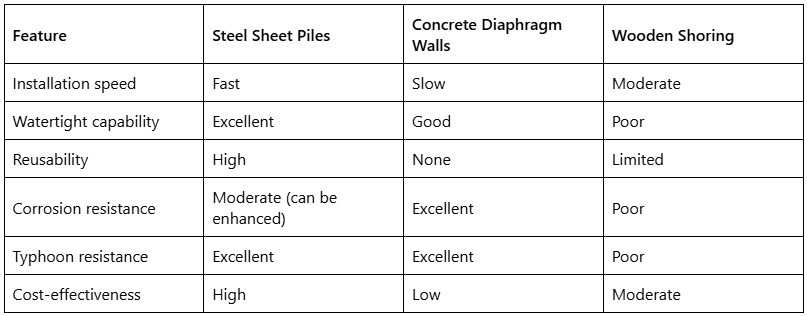

Unlike concrete diaphragm walls or wood shoring, steel sheet piles offer several advantages for Philippine construction conditions:

When to Use Steel Sheet Piling?

Steel sheet piling is the preferred solution in several construction scenarios:

- Waterfront structures: For ports, harbors, and marine facilities throughout the Philippines, particularly in coastal cities like Davao, Manila, and Cebu, sheet piles create resilient structures that withstand harsh saltwater conditions and wave action. Projects include:

- Ferry terminals

- Commercial ports

- Fishing harbors

- Marina developments

- Coastal protection systems

- Deep Excavation support: When deep excavations are required in urban settings to prevent soil collapse, sheet piles provide critical temporary or permanent support. Common applications in Philippine cities include:

- High-rise foundation construction

- Underground parking facilities

- Utility installation in dense urban environments

- Basement construction in limited spaces

- Flood Protection Systems: Essential in flood-prone regions across the Philippines during typhoon season, sheet pile walls form the backbone of many flood protection systems. They’re particularly valuable in:

- River embankment reinforcement

- Flood diversion channels

- Urban flood defense systems

- Critical infrastructure protection

- Groundwater Control Systems: To create dry working environments in areas with high water tables—a common challenge in many Philippine regions—sheet piles excel at:

- Cofferdams for bridge pier construction

- Dewatering systems for deep foundations

- Cut-off walls for dams and water retention structures

- Groundwater contamination barriers

- Permanent Retaining Walls: For long-term structural support in infrastructure projects, sheet pile walls provide several advantages:

- Minimal excavation requirements

- Faster construction timelines

- Reduced disruption to surrounding areas

- Excellent performance in limited space conditions

- River bank protection: To prevent erosion and stabilize riverbanks during heavy rainfall periods.

See detailed applications of sheet pile walls in construction

How Much Does a Steel Sheet Pile Cost in the Philippines?

The cost of steel sheet piles in the Philippines varies depending on several factors that construction professionals should consider during project planning:

Material Grade Factors

Different steel grades offer varying levels of corrosion resistance and strength:

- Standard carbon steel: Most economical option, suitable for temporary works

- High-strength low-alloy steel: Better strength-to-weight ratio, moderate cost increase

- Marine-grade steel: Enhanced corrosion resistance for saltwater exposure, premium pricing

- Specialty coated steel: Maximum protection for aggressive environments, highest cost tier

Profile Dimensions Impact

Sheet pile dimensions significantly affect pricing:

- Profile depth: Deeper profiles (400-600mm) cost more but provide greater strength

- Web thickness: Thicker webs increase weight and cost but enhance durability

- Section modulus: Higher values indicate stronger piles but at premium prices

Quantity Considerations

Volume purchasing affects unit pricing:

- Projects requiring 50+ tons typically qualify for better unit pricing

- Bulk orders of standard sections receive more competitive rates

- Custom or specialty sections command higher prices regardless of volume

Logistical Factors

The Philippines’ archipelagic geography introduces unique cost considerations:

- Import duties: Some specialized profiles may incur additional import costs

- Shipping to remote islands: Can significantly increase delivered costs

- Port handling fees: Vary by location and affect overall pricing

Current Market Rates

While prices fluctuate based on global steel markets and supply chain conditions, general price ranges (as of publication) are:

- Standard U-type profiles: ₱45,000-65,000 per ton

- Z-type profiles: ₱50,000-75,000 per ton

- Combined wall systems: ₱60,000-90,000 per ton

For the most current pricing in Davao City and surrounding areas, it’s recommended to request a quote from Davao Golden Hardware. Their team can provide tailored pricing based on your specific project requirements and current market conditions.

What Are the Types of Sheet Piles?

Steel sheet piles come in various profiles, each designed for specific applications in Philippine construction conditions:

1. Z-type Sheet Piles

These are the most common type, featuring a Z-shaped cross-section that provides excellent sectional properties and high moment of inertia. Z-type sheet piles are ideal for deep excavations and waterfront structures where significant bending resistance is required.

2. U-type Sheet Piles

With their U-shaped profile, these sheet piles offer good bending resistance while being lighter than Z-piles. They’re commonly used in temporary works and where driving conditions are difficult.

3. Straight Web Sheet Piles

These have a simpler profile with minimal bending resistance but excellent interlock strength. They’re suitable for cofferdams and circular structures.

4. Combined Wall Systems

For extremely demanding applications, combination walls using sheet piles integrated with larger structural elements like king piles or tubular piles provide exceptional strength.

Installation Methods in Philippine Conditions

The tropical climate and varied soil conditions across the Philippines require specific installation approaches:

- Vibratory hammers: Ideal for sandy soils common in coastal areas of Davao and other Philippine cities, vibratory hammers offer:

- Reduced noise impact in urban environments

- Faster driving rates in appropriate soils

- Lower impact on surrounding structures

- Enhanced sheet pile integrity during installation

- Impact hammers: Better suited for clay-rich soils found in many inland construction sites:

- Greater penetration capability in cohesive soils

- More effective in dense or compacted ground conditions

- Higher energy transfer for difficult driving situations

- Necessary for reaching design depths in resistant strata

- Press-In Method: Preferred in noise-sensitive urban areas to minimize disruption to surrounding communities:

- Near-silent operation for urban construction

- Minimal vibration impact on adjacent structures

- Precise positioning and alignment control

- Suitable for restrictive working environments

Why Choose Davao Golden Hardware for Your Sheet Pile Needs

As the leading supplier of construction materials in Mindanao, Davao Golden Hardware offers several advantages:

- Extensive inventory: Immediate availability of various sheet pile profiles.

- Technical expertise: Guidance on selecting the right sheet pile type for your specific project.

- Nationwide delivery: Logistics solutions to deliver materials anywhere in the Philippines.

- Quality assurance: All steel sheet piles meet international standards for structural integrity.

Conclusion: Maximizing Success with Steel Sheet Piles

Steel sheet piles remain an indispensable component in modern construction throughout the Philippines. Their versatility, strength, and reliability make them the preferred choice for challenging geotechnical applications. Whether you’re developing waterfront infrastructure in Davao or managing groundwater in a construction project elsewhere in the country, understanding the right sheet pile solution can significantly impact your project’s success.

For more information or to discuss your specific requirements, contact the steel sheet pile experts at Davao Golden Hardware today.

Additional Resources

Expert Installation Partners

For professional installation services, Davao Golden Hardware recommends these certified installation contractors:

- Mindanao Piling Services

- Philippine Marine Construction

- Metro Davao Builders

- National Infrastructure Specialists

This comprehensive guide is maintained and updated quarterly by the technical team at Davao Golden Hardware, Inc. Last updated: March 2025.