Description

Ultimate Guide to Perfect Cold Formed U Type Steel Sections: Professional Solutions

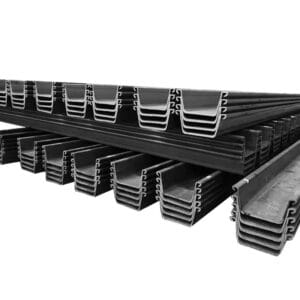

This type of steel sections represent a cornerstone of modern construction and engineering solutions. These lightweight yet robust steel components have revolutionized the way we approach structural support in both residential and commercial projects. Their versatility and strength have made them indispensable in modern architecture, from small-scale renovations to large industrial complexes. Engineers and contractors consistently choose these sections for their exceptional durability and cost-effectiveness in structural applications. The innovative cold-forming process ensures precise dimensions and superior finish quality, making them the preferred choice for projects requiring exact specifications. With increasing demands for sustainable and efficient building materials, Cold Formed U Type sections have emerged as a leading solution in the construction industry. In this comprehensive guide, we’ll explore everything you need to know about Cold Formed U Type sections, from their manufacturing process to practical applications.

Read More

What Are Cold Formed U Type Steel Sections?

This steel sections are precision-engineered structural components manufactured through a sophisticated cold-forming process. As defined by the Steel Framing Industry Association (SFIA), unlike hot-rolled steel, these sections are formed at room temperature, resulting in superior dimensional accuracy and surface finish. The manufacturing process involves carefully controlled deformation of steel sheets, which enhances the material’s strength without compromising its structural integrity. This precision engineering ensures that each section maintains consistent properties throughout its entire length, making it ideal for projects that demand high accuracy and reliability.

Manufacturing Process

The production of Cold Formed U Type sections involves several critical stages:

1. Material Selection

- High-grade steel coil selection

- Quality inspection of raw materials

- Material thickness verification

- Chemical composition testing

- Surface condition assessment

2. Cold-Forming Process

- Progressive roll forming

- Precision bending at room temperature

- Quality control monitoring

- Surface treatment and finishing

- Dimensional calibration checks

3. Quality Assurance

- Dimensional accuracy testing

- Structural integrity verification

- Coating thickness measurement

- Load-bearing capacity testing

- Surface finish inspection

Maintenance and Care

To ensure long-term performance:

- Regular inspection schedule

- Coating maintenance

- Connection point verification

- Load capacity monitoring

- Corrosion prevention measures

Advantages Over Traditional Methods

Cold Formed U Type sections offer several benefits:

1. Cost-Effectiveness

- Reduced material waste

- Lower transportation costs

- Quick installation

- Minimal maintenance requirements

- Decreased labor expenses

2. Performance Benefits

- High strength-to-weight ratio

- Excellent dimensional stability

- Superior durability

- Versatile applications

- Extended service life with minimal degradation

3. Installation Advantages

- Easy handling

- Simple assembly

- Precise fitting

- Reduced labor requirements

- Flexible modification capabilities for on-site adjustments

Environmental Impact

Contribute to sustainable construction:

- Recyclable materials

- Reduced carbon footprint

- Energy-efficient manufacturing

- Minimal waste production

- Long service life

FAQ

Q: What is the standard delivery time for Cold Formed U Type sections?

A: Standard sizes are typically available within 3-5 business days.

Q: Can custom sizes be manufactured?

A: Yes, we offer custom manufacturing services with lead times varying by specification.

Q: What is the warranty period?

A: Our products come with a standard 10-year warranty against manufacturing defects.

Technical Specifications

Our Cold Formed U Type sections are manufactured to meet the following specifications:

- Material: High-grade structural steel

- Standard Lengths: 3m, 6m, and custom sizes available

- Thickness Range: 1.0mm to 3.0mm

- Surface Treatment: Galvanized or powder-coated options

- Load-Bearing Capacity: Varies by size (see technical documentation)

Applications and Uses

Cold Formed U Type sections find applications across various industries:

Construction Industry

- Structural framing

- Wall supports

- Ceiling systems

- Partition frameworks

Installation Guidelines

Proper installation ensures optimal performance:

1. Pre-Installation Planning

- Site assessment

- Load calculation

- Support spacing determination

- Tool preparation

2. Installation Steps

- Marking and measuring

- Cutting and fitting

- Securing and fastening

Final alignment and adjustment