Description

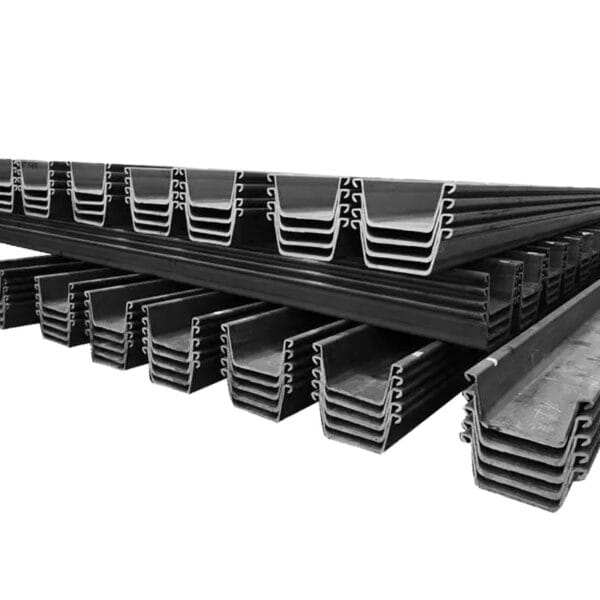

HOT ROLLED U TYPE Steel Sections: Best Solutions for Heavy-Duty Construction

Hot-Rolled U-Type steel sections are designed for heavy-duty construction applications. Their superior strength and load-bearing capabilities make them ideal for use in infrastructure projects and large-scale buildings. These products are specifically designed and manufactured to meet the highest standards in the industry. They undergo rigorous quality control processes to ensure that they are durable, reliable, and suitable for a wide range of applications. Whether you’re working on a small residential project or a large industrial development, these materials provide the strength and support needed to ensure the success of your construction. Their versatility and adaptability make them an essential component in modern engineering and architecture.

Read More

What Are Hot Rolled U Type Steel Sections?

These steel sections are heavy-duty structural components manufactured through an advanced hot-rolling process. World Steel Association, unlike cold-formed steel, these sections are formed at high temperatures (typically above 1700°F), resulting in superior strength and excellent load-bearing capacity. The manufacturing process involves carefully controlled heating and shaping of steel billets, which optimizes the material’s structural properties while ensuring maximum durability. This thermal processing ensures that each section delivers consistent performance under heavy loads, making it perfect for projects that require exceptional strength and stability.

Manufacturing Process

The production of Hot Rolled U Type sections involves several critical stages:

- Material Selection

- Premium-grade steel billet selection

- Raw material quality verification

- Dimensional specification check

- Steel grade certification

- Material composition analysis

- Hot-Rolling Process

- Controlled heating to optimal temperature

- Progressive shape formation

- Cooling rate monitoring

- Surface finish control

- Final shape calibration

- Quality Assurance

- Structural strength testing

- Dimensional conformity check

- Heat treatment verification

- Load capacity certification

- Surface quality inspection

Maintenance and Care

To ensure optimal performance:

- Periodic structural inspection

- Rust prevention treatment

- Joint and connection checks

- Structural integrity monitoring

- Protection from environmental factors

Advantages Over Traditional Methods

Hot Rolled U Type sections offer significant benefits:

- Strength Benefits

- Superior load-bearing capacity

- Enhanced structural stability

- High tensile strength

- Excellent stress distribution

- Consistent material properties

- Performance Characteristics

- Outstanding durability

- Reliable structural integrity

- Heat resistance properties

- Weather endurance

- Long-term performance stability

- Application Advantages

- Suitable for heavy loads

- Ideal for large structures

- Excellent welding properties

- High impact resistance

- Versatile use in construction

Environmental Impact

Contributing to sustainable building:

- Durable lifecycle

- Low replacement frequency

- Efficient material usage

- Recyclable components

- Minimal environmental impact

FAQs

Q: What is the typical lead time for Hot Rolled U Type sections?

A: Standard sizes are usually available within 7-10 business days.

Q: Are custom specifications available?

A: Yes, we offer custom sizing and specifications with lead times based on project requirements.

Q: What warranty coverage is provided?

A: Our hot-rolled products come with a comprehensive 15-year structural warranty.

Would you like me to expand on any particular section or add more technical details?

Technical Specifications

Our Hot Rolled U Type sections are manufactured to meet the following specifications:

Surface Treatment

- Mill Scale Finish

- Surface Roughness: Ra 6.3 μm max

- Shot Blasting Available

- Primer Coating Optional

- Hot-Dip Galvanizing Available

Tolerance Levels

- Length: ±5mm

- Web Height: ±2mm

- Flange Width: ±2mm

- Thickness: ±0.3mm

- Straightness: 0.2% of total length

Applications and Uses

Hot Rolled U Type steel sections are widely used across various industries, providing robust structural support for demanding applications.

Construction Industry

- Heavy industrial building frameworks

- Multi-story building support structures

- Bridge girder reinforcements

- Large-scale foundation supports

- Load-bearing wall systems

Industrial Applications

- Heavy machinery support frames

- Industrial equipment foundations

- Crane runway beams

- Factory floor support systems

- Heavy-duty storage rack structures

Infrastructure Projects

- Railway bridge components

- Highway overpass supports

- Underground tunnel reinforcements

- Port facility structures

- Power plant structural elements

Marine Applications

- Shipyard construction supports

- Dock and pier structures

- Marine terminal frameworks

- Offshore platform components

- Harbor facility structures

Industrial Applications

Hot Rolled U Type steel sections deliver reliable structural support for demanding industrial environments.

Industrial Applications

- Heavy machinery support frames and bases

- CNC machine foundations

- Industrial press supports

- Generator mounting structures

- Manufacturing facility infrastructure

- Assembly line support systems

- Production equipment platforms

- Conveyor system frameworks

- Warehouse and storage solutions

- High-capacity storage racks

- Mezzanine floor supports

- Loading dock structures

- Processing plant structures

- Chemical plant frameworks

- Refinery support systems

- Food processing equipment bases

- Material handling equipment

- Overhead crane supports

- Hoist system frameworks

- Lifting equipment bases

Infrastructure Projects

Infrastructure projects demand reliable and robust structural components for long-term stability and safety.

Infrastructure Projects

- Railway bridge construction with high stress-bearing capabilities

- Highway overpass support systems for heavy vehicular traffic

- Underground tunnel reinforcement for maximum structural integrity

- Public transportation terminal framework and support structures

- Power transmission tower foundations and reinforcements

Installation Guidelines

Professional installation of Hot Rolled U Type steel sections requires precise methods and adherence to safety standards for optimal structural performance.

Installation Guidelines

- Foundation preparation with proper leveling and anchoring points according to structural specifications

- Heavy-duty lifting equipment requirements with certified crane operators for safe handling

- Precise alignment and positioning using laser leveling systems for maximum stability

- Professional welding procedures following AWS D1.1 structural welding code standards

- Quality control inspection of all connections and load-bearing points after installation