Description

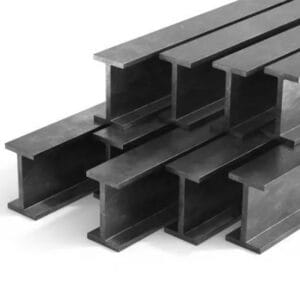

Understanding Steel Tubes: Essential Components in Modern Construction and Industry

These tubes are versatile industrial components that offer exceptional strength and reliability across various applications. According to the World Steel Association, these precision-manufactured tubes provide essential solutions for structural, mechanical, and automotive applications. Their diverse capabilities make them fundamental elements in modern engineering and construction projects.

Read More

Key Characteristics

- High tensile strength

- Superior load-bearing capacity

- Excellent torsional resistance

- Good thermal conductivity

- Enhanced corrosion resistance

Steel tubes are engineered to meet precise industry standards for optimal performance.

Technical Specifications

- Steel Grade: ASTM A500/JIS G3444

- Surface Finish: Hot-dipped galvanized or black

- Pressure Rating: Varies by application

- Standard Lengths: 6m and 12m

- Wall Thickness: According to schedule

These tubes provide versatile solutions across numerous industrial applications.

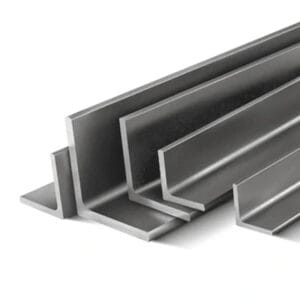

Applications and Uses

- Structural support systems

- Process piping networks

- Mechanical equipment

- Transportation systems

- Underground utilities

Industrial facilities rely on these tubes for their robust operational requirements.

Industrial Applications

- Process piping systems

- Heat exchanger components

- Hydraulic systems

- Manufacturing equipment

- Agricultural machinery

Infrastructure projects demand reliable and durable components for long-term stability.

Infrastructure Projects

- Building framework systems

- Underground utility networks

- Transportation infrastructure

- Industrial facility piping

- Public utility systems

Installation Guidelines

- Proper alignment and support

- Correct joining techniques

- Pressure testing procedures

- Protective coating application

- Regular inspection protocols

FAQ

Q: What sizes of steel tubes do you offer?

A: We offer various standard sizes and can accommodate custom dimensions based on project requirements.

Q: What is the standard delivery time?

A: Standard sizes are typically available within 5-7 business days. Custom orders may require additional processing time.

Q: Do you provide technical support for installation?

A: Yes, our technical team offers comprehensive support for product selection, specifications, and installation guidance.

Q: What types of tubes are available?

A: We offer both seamless and welded steel tubes, with various surface finishes and specifications to meet different applications.

Q: What quality standards do your steel tubes meet?

A: Our steel tubes comply with international standards such as ASTM A500 and undergo rigorous quality control testing.

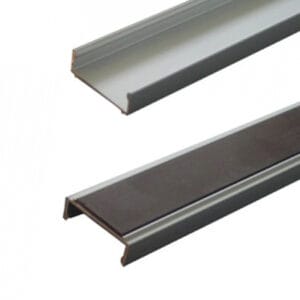

Applications and Uses

- Sizes: Available in a wide range of diameters to accommodate different applications and load requirements.

- Wall Thicknesses: Offered in various thicknesses to ensure the necessary strength and rigidity.

- Lengths: Standard lengths are available, but custom lengths can be provided to match specific project needs.

- Standards: Manufactured according to international standards to ensure consistent quality and performance.

Please call for inquiries on specifications.

You may also send us an email at info@davaogoldenhardware.ph or send us a message here for more inquiries.

Industrial Applications

Industrial Applications

- Manufacturing process lines

- Heat exchanger systems

- Hydraulic and pneumatic systems

- Industrial machinery components

- Equipment support structures

Infrastructure projects demand reliable and durable components for long-term stability.

Installation Guidelines

Installation Guidelines

- Site preparation and system layout planning

- Proper cutting and fitting procedures

- Professional welding and joining techniques

- Pressure testing and leak detection

- Quality inspection and certification

Each installation point includes:

Proper safety protocols

Industry standard compliance

Professional expertise requirements

Quality control measures

Performance verification